Repair Cracked Concrete Slabs

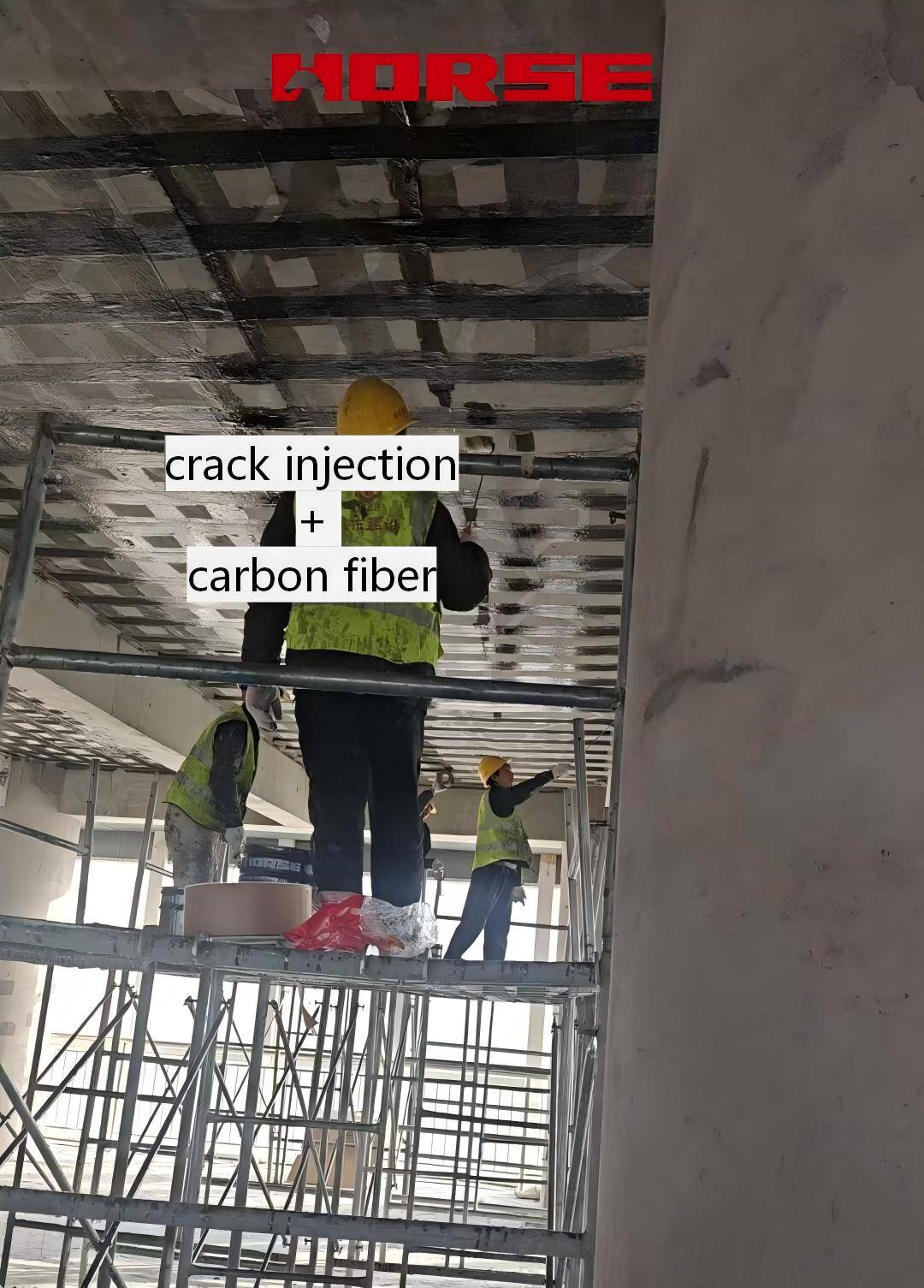

Crack repair+Carbon fiber

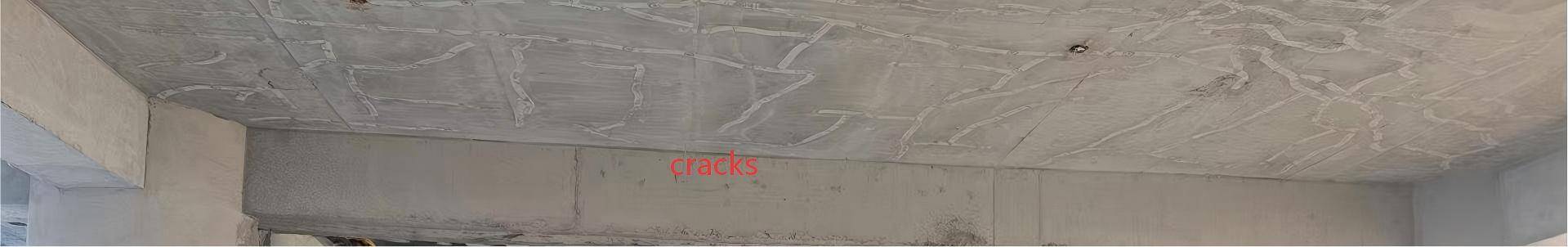

This project is a residential development under construction by Country Garden, with the main structure already completed. During the structural inspection prior to interior decoration, several floor slabs were found to have cracks of varying degrees. The cracks were mainly irregular and linear in distribution, with some exceeding 0.2mm in width and extending deep into the floor slabs.

Project Overview

This project is a residential development under construction by Country Garden, with the main structure already completed. During the structural inspection prior to interior decoration, several floor slabs were found to have cracks of varying degrees. The cracks were mainly irregular and linear in distribution, with some exceeding 0.2mm in width and extending deep into the floor slabs.

These cracks not only affect the durability of the structure but may also lead to leakage problems, posing a safety hazard and impacting the living experience. To ensure structural safety and meet the design service life requirements, the project team decided to adopt a reinforcement scheme involving "crack repair + carbon fiber bonding."

Crack Repair Construction

Crack Cleaning

Use an angle grinder with a wire brush to remove surface mortar, oil stains, and loose aggregates from the crack surface. Then, use a high-pressure blower to thoroughly clean the dust from the groove, ensuring the repair surface is dry and dust-free.

Adhering Injection Bases

Attach an injection base every 30-50cm along the crack. More bases should be placed at crack intersections and wider areas. After attaching the bases, seal the crack surface with sealant, leaving only the injection ports of the bases exposed.

Pressure Injection epoxy

Use low-viscosity, high-strength HM-120L epoxy resin grout. Inject the grout from the bases using a manual injection device, working from bottom to top, until grout overflows from the adjacent base. After injection, let it stand for 24 hours to ensure complete curing of the grout.

Surface Treatment

After the grout has cured, remove the injection bases and sealant. Use an angle grinder to smooth the crack surface, ensuring a smooth transition with the surrounding concrete surface.

Crack repair inspection: Through tapping and listening to the sound, and using ultrasonic testing, it was confirmed that the crack was fully filled with the repair adhesive and there were no voids.

Carbon Fiber Reinforcement Construction

Substrate Preparation

The surface of the floor slab is ground to remove concrete laitance and expose the solid base layer. The surface is then wiped with acetone to ensure it is free of oil and dust. Surface depressions are leveled with epoxy putty to create a smooth and clean bonding surface.

Application of Primer

Epoxy primer is mixed according to the specified ratio and evenly applied to the prepared floor slab surface. The primer thickness is controlled at 0.2-0.3mm. After the primer is touch-dry (approximately 1-2 hours), the next step of construction is performed.

Bonding of Carbon Fiber Fabric

300g/m² unidirectional carbon fiber fabric is used for this reinforcement project. After cutting to the design dimensions, the prepared epoxy impregnation adhesive is evenly applied to the primer surface. The carbon fiber fabric is then smoothly bonded in place, and a special roller is used to repeatedly roll along the fiber direction to remove air bubbles and ensure that the adhesive fully impregnates the fabric.

Surface Protection

After the carbon fiber fabric is bonded and cured, a layer of epoxy protective adhesive is applied to the surface to prevent the carbon fiber fabric from being damaged by ultraviolet rays and mechanical damage.

Carbon fiber bonding inspection: The bonding quality is tested using the hammer tapping method. The effective bonding area should be greater than 95%. For localized areas with voids, adhesive is injected using a syringe for repair.

Strength testing: Pull-out tests were conducted on samples taken on-site, and the bond strength between the carbon fiber fabric and the concrete met the specifications.

After the reinforcement was completed, third-party testing confirmed that the bending stiffness and crack resistance of the floor slab were significantly improved, effectively ensuring the structural safety.