Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

Concise Q&A guide on carbon fiber fabric for concrete repair & structural strengthening.

Construction Preparation and Process

Q: What treatments are needed for the concrete surface before construction?

· Remove surface oil, loose concrete, and protrusions; use epoxy resin to repair cracks (width > 0.2mm requires pre-grouting).

· Round off corners with a radius ≥20mm to ensure even adhesive distribution.

Q: What are the key steps for pasting carbon fiber fabric?

· Apply base adhesive evenly and wait until it is dry to the touch (about 1-2 hours) before pasting.

· Use a roller to press out bubbles while pasting; ensure fiber direction overlap ≥200mm, and stagger layers by at least 50mm. Avoid bending the fabric at corners.

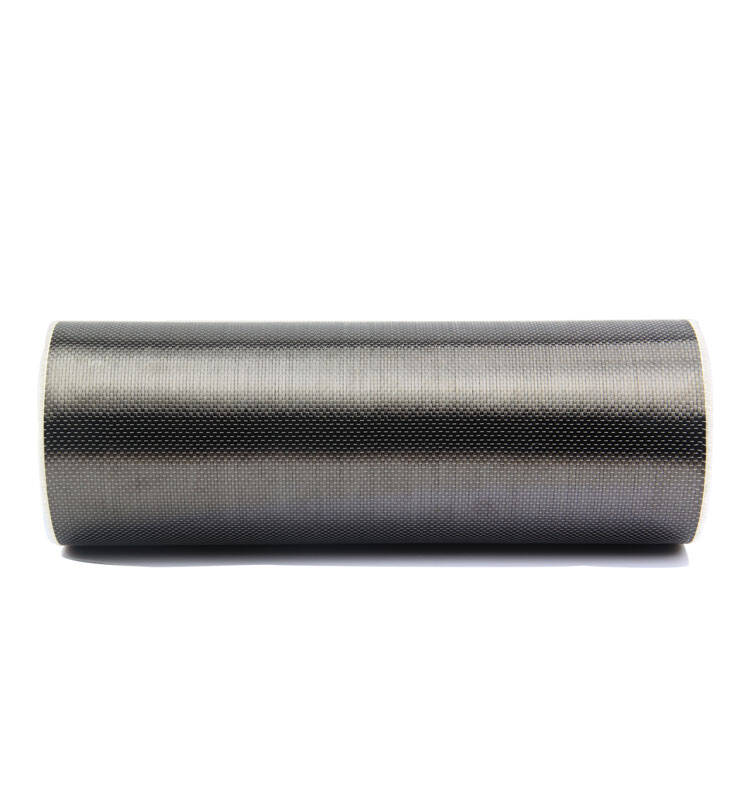

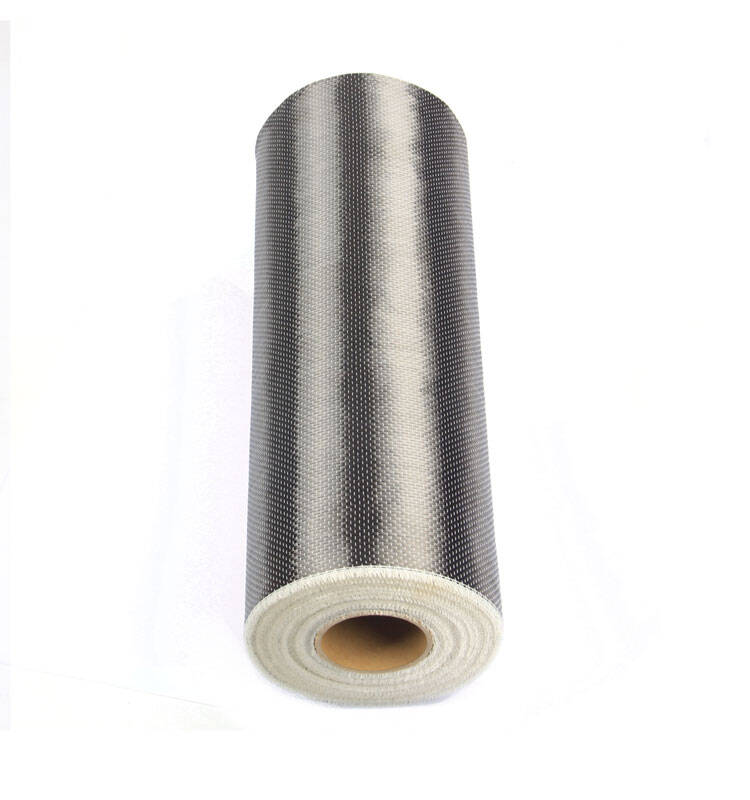

Material Selection and Properties

Q: How to choose the right type of carbon fiber fabric?

· For tensile/shear reinforcement : Select high-strength Grade I (tensile strength ≥3400MPa, e.g., 300g/m²).

· For durability reinforcement (e.g., coastal/chemical environments): Choose alkali-resistant type with ZrO₂ additives.

Q: What are the precautions for using adhesive?

· Use epoxy resin; heat it to 40℃ in low temperatures (<5℃) to improve flowability.

· Mix base adhesive and impregnating resin strictly according to the manufacturer’s ratio.

Common Problems and Solutions

Q: How to handle air bubbles after pasting?

· If a single bubble area >10,000mm², drill holes and inject adhesive to repair; if >30mm², cut and re-paste the section to ensure effective bonding area ≥95%.

Q: How to prevent carbon fiber fabric from lifting?

· Let the pasted fabric sit undisturbed for 24 hours; use clamps if necessary. Reinforce corner areas with extra adhesive to prevent lifting.

Safety and Standards

Q: What safety risks should be noted during construction?

· Carbon fiber is conductive: keep away from electrical sources, and wear insulated gloves.

· Store adhesive in a sealed, fireproof location, and ensure good ventilation in the work area.

Comparison with Traditional Methods

Q: What are the advantages of carbon fiber fabric compared to steel plate reinforcement?

· Lightweight: Does not increase structural load, suitable for space-constrained scenarios (e.g., bridges, historic buildings).

· Fast construction: No heavy equipment needed; cures at room temperature within 24 hours, reducing project duration by over 50%.

· Corrosion-resistant: Resists acid, alkali, and salt spray, ideal for marine or industrial environments. Maintenance costs are lower than steel.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.