Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

What to do if carbon fiber bond strength is insufficient?

The core cause of insufficient bonding strength

Material System Compatibility Issues

Adhesive Performance Defects:

Failure to select a dedicated impregnating adhesive for carbon fiber cloth (e.g., misusing conventional epoxy resin adhesive) results in poor wettability between the adhesive layer and the fiber bundle, resulting in insufficient interfacial bonding strength.

Improper adhesive curing agent ratio (e.g., excessive/insufficient curing agent) causes embrittlement or incomplete curing of the adhesive layer, resulting in tensile strength below the standard requirement (GB 50728-2011 stipulates a tensile strength of ≥30 MPa for impregnating adhesives).

Improper adhesive storage (e.g., high temperature and humidity) causes component separation or deterioration, reducing bonding performance.

Poor Compatibility between Carbon Fiber Cloth and Substrate:

The carbon fiber cloth's mass per unit area does not match the adhesive's viscosity (e.g., using low-viscosity adhesive on high-weight cloth can easily lead to insufficient penetration of the adhesive layer).

The concrete substrate is too weak (below C20), resulting in insufficient surface compressive strength. Cohesive failure of the substrate occurs under load, which is mistakenly interpreted as insufficient bond strength.

Lack of standardized construction techniques

Incomplete base preparation:

Floating slurry and oil stains on the concrete surface were not removed (residues remained even after wiping with acetone), resulting in a "false bond" between the adhesive layer and the substrate;

The base flatness exceeded the standard (deviation > 5mm/m), the leveling adhesive did not completely fill the depressions, the adhesive layer thickness was uneven, and stress concentration areas were prone to cracking;

The base moisture content was too high (> 6%), causing bubbles to form during the adhesive curing process, which compromised the interfacial bond.

Improper pasting operation:

Insufficient impregnation adhesive was applied (< 0.2kg/m2), resulting in incomplete saturation of the carbon fiber bundles, resulting in dry fiber areas;

During pasting, a dedicated roller was not used to compact the fibers in the direction of the fibers, preventing complete air removal, resulting in a hollowing rate > 5% (the standard allows a hollowing rate of ≤ 2%);

When pasting multiple layers, the next layer was applied before the previous layer had reached finger-dryness (usually 2-4 hours), weakening the interlayer bond.

Environmental interference

Uncontrolled temperature and humidity:

Ambient temperatures below 5°C slow the adhesive's curing rate, with the cure rate falling below 60% after 24 hours.

Relative humidity above 85% causes moisture absorption on the adhesive surface, forming a water film and reducing interfacial bond strength (measured decreases of 30%-50%).

Improper post-curing:

During the curing period (usually 7 days), vibration or external force disturbances can cause micro-displacement between the adhesive layer and the substrate.

High temperature exposure can cause thermal aging of the adhesive layer, resulting in a decrease in elastic modulus and weakening of bonding performance.

Methods for detecting insufficient bond strength

On-site Testing Methods

Pull-off Test (according to GB/T 50367-2013):

A 50mm diameter steel puller is used to bond the carbon fiber sheet to the adhesive through epoxy resin adhesive, applying axial tension until failure.

Criteria: ① Failure is adhesive failure or cohesive failure within the substrate, with a tensile strength ≥ 2.5 MPa (C30 concrete substrate); ② If the fiber sheet fails, the bond strength is acceptable.

Ultrasonic Testing:

A 2.5MHz probe is used to scan the bonded area. Hollow areas will show abnormal wave velocities (15%-20% lower than normal), indirectly reflecting the bond quality.

Especially focus on testing overlaps (length ≥ 100mm) and corners, as these areas are prone to weak bonding.

Treatment measures for insufficient bonding strength

Minor deficiency (pull-out strength 1.5-2.5 MPa, hollowing rate 2%-5%)

Glue injection repair:

Using a 0.8 mm diameter needle, drill holes at 20 mm intervals in the hollow area, reaching the concrete surface.

Inject modified epoxy resin glue (viscosity 500-1000 mPa·s for easy penetration) at a pressure of 0.2-0.3 MPa until the glue overflows from adjacent holes.

After curing for 24 hours, perform another pull-out test to confirm that the strength meets the requirements.

Moderate deficiency (pulling strength 1.0-1.5 MPa, hollowing rate 5%-10%)

Partial excision and re-applying:

Use a utility knife to cut the carbon fiber sheet 50 mm from the edge of the hollow area (avoid damaging the base material), remove any remaining adhesive, and sand the base layer.

Reapply primer (0.1-0.2 mm thick) and leveling adhesive, then apply a new carbon fiber sheet, extending the overlap to 150 mm. Ensure the adhesive layer is full in the overlap area with the original sheet.

Use a pressurized fixture (0.1 MPa) to secure for 24 hours. Inspect after curing.

Severe deficiency (pull-out strength <1.0 MPa, hollowing rate >10%)

Overall rework:

Completely remove all pasted carbon fiber sheeting and grind the concrete surface with an angle grinder (80-grit grinding wheel) to expose fresh aggregate.

Retest the substrate strength (rebound or core drilling). If the strength is less than C20, treat with a primer or add a concrete leveling layer.

Replace with a qualified adhesive (factory inspection report required). Strictly adhere to specifications, ensuring each process is inspected and accepted before proceeding to the next.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

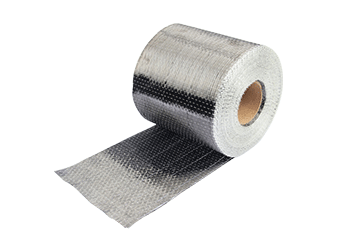

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

High strength, unidirectional carbon fiber fabric pre-saturated to form a carbon fiber reinforced polymer (CFRP) fabric used to strengthen structural concrete elements.

High strength, unidirectional carbon fiber sheet pre-saturated to form a carbon fiber reinforced polymer (CFRP) sheet used to strengthen structural concrete elements.