Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

Prestressed carbon plates, however, actively apply precompressive stress, upgrading their function from passive assistance to active reinforcement. This addresses the key shortcomings of conventional carbon plates in terms of load-bearing efficiency, crack control, and increased stiffness.

Conventional carbon plates (non-prestressed) passively support loads and only begin to function after the structure deforms under load.

Prestressed carbon plates, however, actively apply precompressive stress, upgrading their function from passive assistance to active reinforcement. This addresses the key shortcomings of conventional carbon plates in terms of load-bearing efficiency, crack control, and increased stiffness.

Core Complementary Point: A Performance Leap from "Passive" to "Active"

| Comparison Dimensions | Ordinary Carbon Plate (Non-Prestressed) | Prefractory Carbon Plate (Active Reinforcement) | Complementary Value |

| Stress Timing and Efficiency | The carbon plates are first "pulled" to participate in the load after the structure is loaded and deformed (passive response). | During reinforcement, prestress is applied to the carbon plates, which is then transferred to the component via anchors to offset some of the load in advance (active intervention). | This prevents the carbon plates from being "idle," allowing them to directly bear the critical tensile forces. This increases material utilization by over 50%, resulting in greater reinforcement effectiveness for the same amount of material. |

| Crack Control | It can only "limit the expansion of existing cracks" but cannot close them. If cracks are already wide, they may continue to grow even after reinforcement. | Prestressing can apply "precompression" to the tensile zone of the component, directly closing it. It can also treat existing cracks ≤0.3mm while simultaneously suppressing the formation of new cracks. | This upgrade from "passive crack caulking" to "active crack closure" completely solves the problem of ordinary carbon plates being unable to repair cracks, preventing crack-related corrosion and structural degradation. |

| Restoring Structural Stiffness | This only "slows down" the rate of stiffness loss but cannot correct existing excessive deflection (such as mid-span sagging). | Prestressing can "push upward" the tensile zone of the component, directly lifting the deflected area (e.g., by 2-5mm at mid-span), restoring or even increasing stiffness. | This addresses the pain point of conventional carbon plates, which only increase strength without stiffness, improving bridge driving comfort (avoiding bumps) while also eliminating secondary damage caused by insufficient stiffness. |

Heavy-Load Adaptability | When subjected to heavy-load vehicles, the structure is prone to initial excessive deformation, and the carbon plate's response is delayed, making it prone to "exceeding the limit even after reinforcement." | Prestressing offsets 30%-50% of the live load effect in advance, minimizing the actual stress on the component during heavy loads and strictly controlling deformation. | This meets "heavy-load upgrade requirements" that ordinary carbon plates cannot handle (e.g., upgrading a bridge from Highway-I to Heavy-Load), avoiding the problem of being unable to withstand heavy loads even after reinforcement. |

Essential Logic: Addressing the "Long-Lasting Defect of Ordinary Carbon Plates"

The core issue with ordinary carbon plates is that they are "out of sync" with the structural load—the structure deforms and cracks first before the carbon plates begin to work, effectively acting as a "post-remediation" measure. Prestressed carbon plates, on the other hand, apply stress in advance, allowing them to "synchronize" with the structure and even "bear the load in advance." This is a combination of "preemptive prevention plus proactive reinforcement," fundamentally addressing the shortcomings of ordinary carbon plates, which are passive, inefficient, and unable to repair damage. They are particularly suitable for bridge reinforcement applications with stringent requirements for crack control, stiffness, and load-bearing capacity.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

High strength carbon fiber reinforced polymer (CFRP) strip / laminate / plate for structural strengthening and concrete repair

Prestressed carbon fiber reinforced polymer(CFRP) plate for slab, beam strengthening to increase stiffness, reduce distortion and deflection of members, reduce the cracks, avoid and stop cracking.

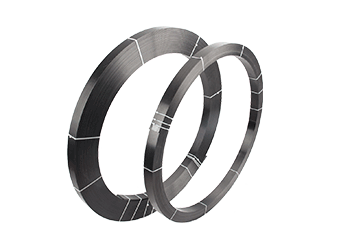

Prestressed carbon fiber laminate circular anchorage system includes rigid anchorage, carbon fiber laminate and adhesive, specially designed for bridges, buildings and steel structure reinforcement.